Advanced Manufacturing

- MJF 3D Printing (Multi Jet Fusion)

- Ideal for manufacturing end-use parts, jigs, and prototypes with high precision and durability.

- Injection Molding

- Thanks to our innovative process, we can produce small to medium batches without the added tooling costs, making it a cost-effective solution for various production needs.

- FDM 3D Printing (Fused Deposition Modeling)

- Perfect for small batches and rapid prototyping, offering quick turnaround times and reliable results.

- Resin 3D Printing (SLA/DLP)

- Utilizes production-grade resins for end-use products and prototype resins for early-stage development.

- Offers a wide variety of materials customized to your project’s needs, with professional consultation to help select the right material for each stage.

MJF 3D Printing (Multi Jet Fusion)

- High-precision, durable end-use parts, jigs, and prototypes.

- Ideal for industrial applications requiring strength and accuracy.

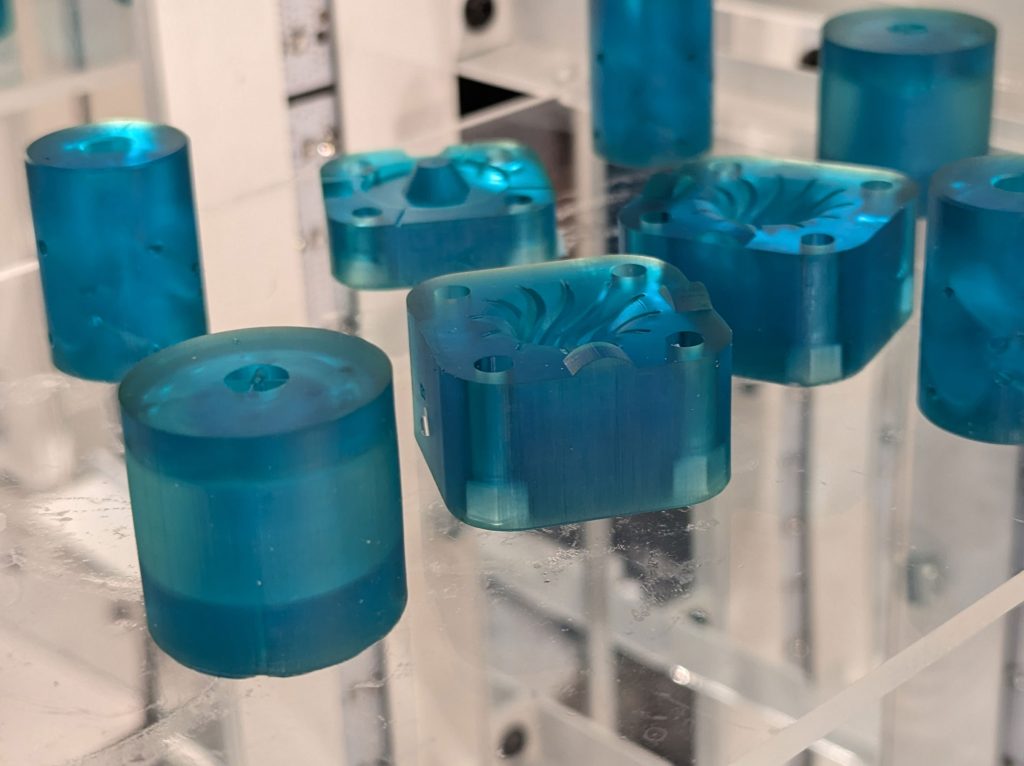

Advanced Short-Run Molding

- Cost-effective solution for small to medium production series, eliminating high tooling costs.

- Perfect for complex geometries and intricate part designs that traditional molding can’t achieve.

- Delivers consistent, high-quality results with rapid turnaround.

FDM 3D Printing (Fused Deposition Modeling)

- Fast and reliable for small batches and rapid prototyping.

- Ideal for functional prototypes and low-volume manufacturing.

- Diverse material selection with options in a wide range of colors, including industrial-grade thermoplastics, flexible polymers, and temperature-resistant compounds—tailored to your project’s specific needs

Resin 3D Printing (MSLA – Masked Stereolithography)

- High-precision printing for end-use parts and detailed prototypes with a flawless surface finish.

- Advanced MSLA technology ensures ultra-fine details and exceptional accuracy.

- Diverse resin selection with rigid, flexible, and heat-resistant options in various colors.

- Perfect for high-detail, functional, and aesthetically refined applications.