FDM (Fused Deposition Modeling)

Overview

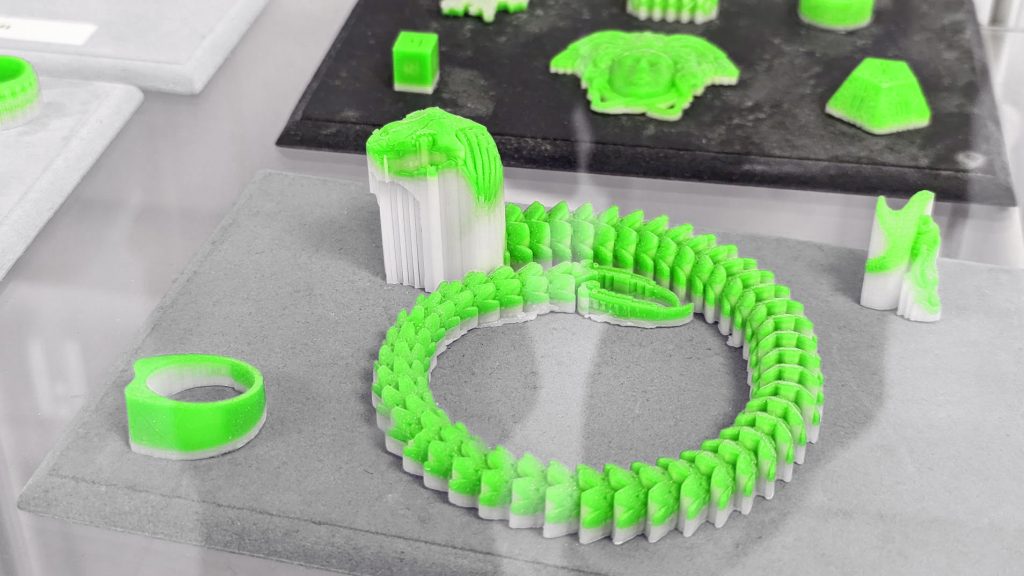

FDM is a well-known and widely used 3D printing technology that extrudes thermoplastic filaments layer by layer to create parts.

It is highly versatile, cost-effective, and ideal for rapid prototyping and functional applications requiring durable materials.

Advantages

- Affordable & Scalable – Great for low-volume production and prototyping.

- Wide Range of Materials – ABS, PLA, PETG, Carbon-Fiber, Nylon, and high-performance polymers.

- Durability & Strength – Suitable for mechanical and industrial parts.

- Fast Turnaround – Ideal for quick, functional prototypes.

- Large Build Volume – Capable of producing big, strong parts efficiently.

Ideal Applications

- Functional prototypes and mechanical parts

- Low-volume manufacturing

- Jigs, fixtures, and tooling

- Custom enclosures and brackets

- Educational and conceptual models